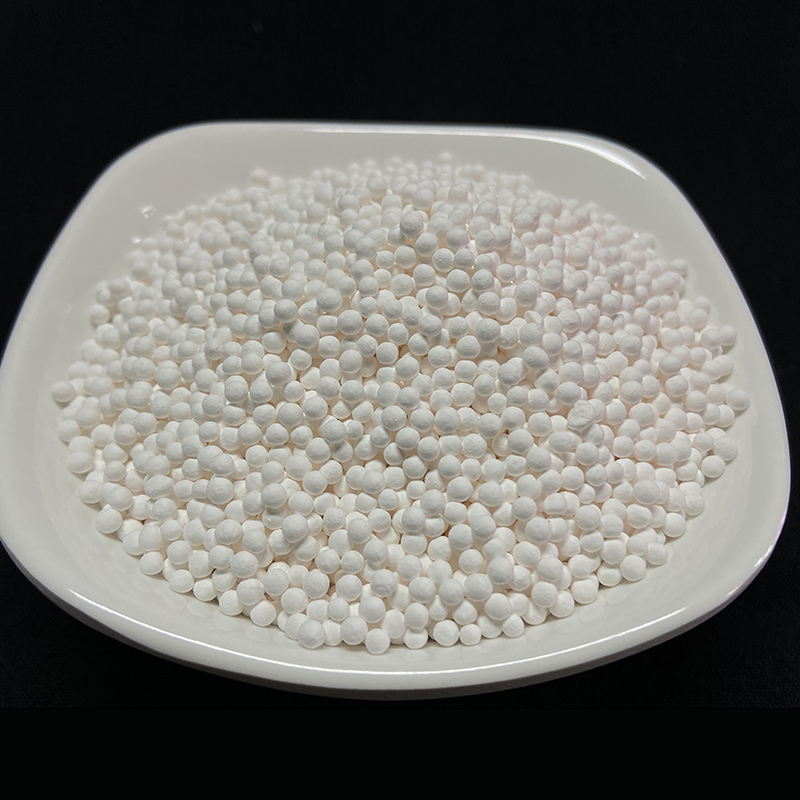

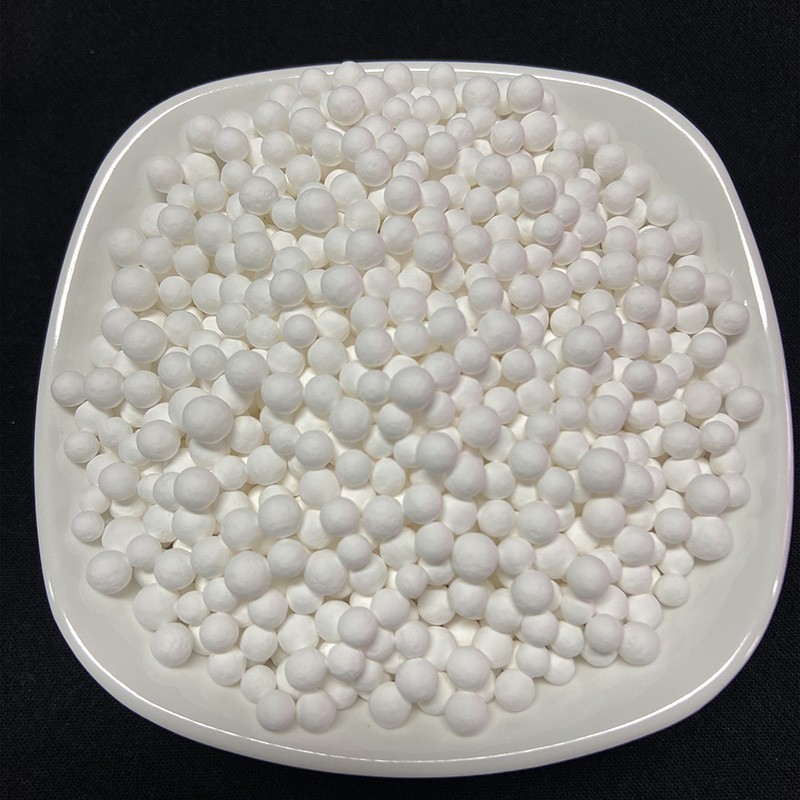

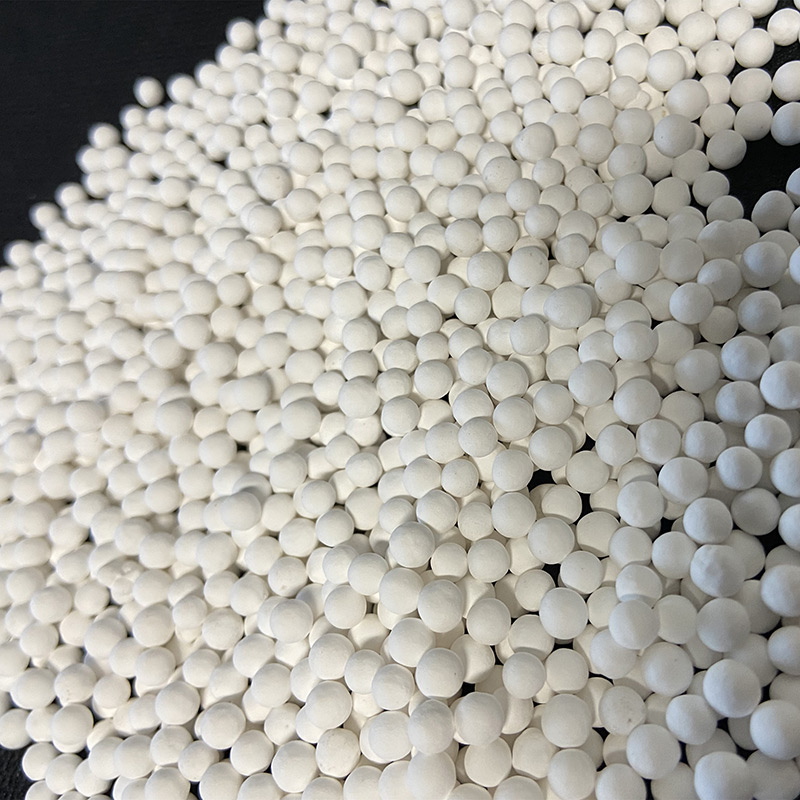

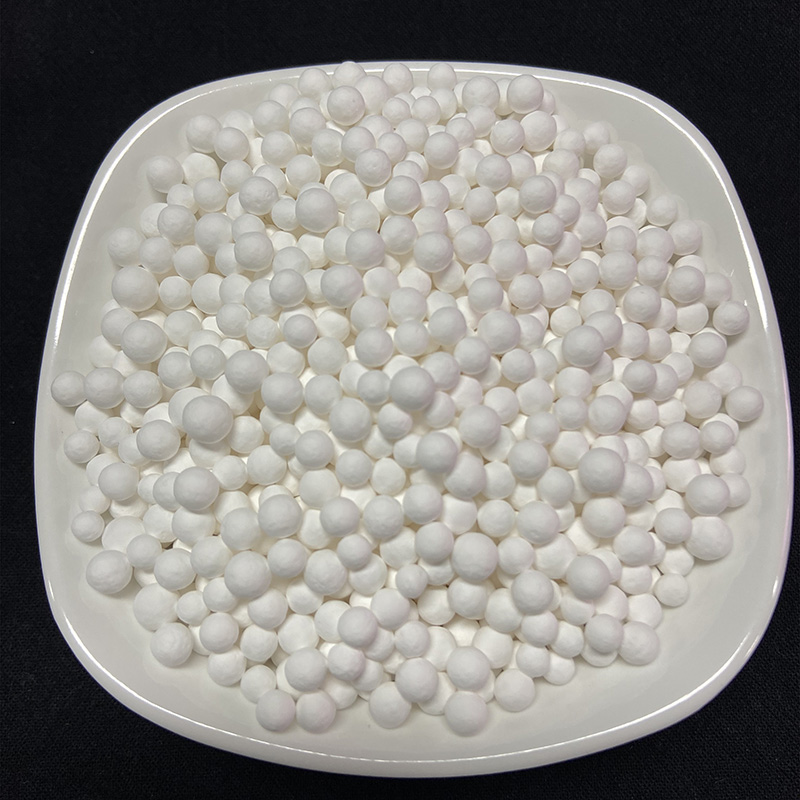

Alumina Ceramic Filler Yakakwira Alumina Inert Bhora/99% alumina ceramic bhora

Zvenyama Uye Kemikari Zvivakwa zve Inert Ceramic Mabhora

| Zvenyama uye zvemakemikari zvimiro zveinert ceramic mabhora | |||||||

| Element | Al2O3% | 60 | 70 | 80 | 90 | 95 | 99 |

| Fe2O3% | ≤0.9 | ≤0.8 | ≤0.6 | ≤0.4 | ≤0.3 | ≤0.1 | |

| Izvo zvakasara zvikamu zvinogona kutsanangurwa kuburikidza nenhaurirano pakati pemutengesi nemutengi kana zvichidikanwa. | |||||||

| kutorwa kwemvura,% | 3±1,Inogona zvakare kutariswa nekutaurirana pakati pemutengesi nemutengi | ||||||

| chikamu, kg/m³ | 2.5-3.0 | 2.7-3.2 | 2.9-3.2 | ≥3.1 | ≥3.2 | ≥3.4 | |

| Kuwanda kwehuwandu, kg/m³ | 1400-1550 | 1400-1650 | 1500-1800 | 1700-1950 | 1800-1950 | ≥1900 | |

| Guruva, kutsemuka kana kutsemuka | Bhegi rimwe chete riri pasi pe5% | ||||||

| Size kutsauka | Uniform sphere, chiyero chehukuru kusvika kudiki dhayamita yeceramic sphere haipfuure 1.2 | ||||||

| Dimensional kushivirira | ≤10mm | ±1.0 | |||||

| 11—25mm | ±1.5 | ||||||

| 26—50mm | ±2.0 | ||||||

| ≥50mm | ±3.0 | ||||||

| Simba rekudonha remahara | Kusarasikirwa mwero ≥99% | ||||||

| Kudzvinyirira simba | φ3 | ≥250 | ≥300 | ≥350 | ≥400 | ≥500 | ≥500 |

| φ6 | ≥800 | ≥1000 | ≥1000 | ≥1200 | ≥1500 | ≥1500 | |

| φ8 | ≥1500 | ≥1600 | ≥1800 | ≥2000 | ≥2500 | ≥2500 | |

| φ10 | ≥2000 | ≥2500 | ≥2800 | ≥3000 | ≥3500 | ≥3500 | |

| φ13 | ≥3000 | ≥3000 | ≥3500 | ≥4000 | ≥5000 | ≥5000 | |

| φ16 | ≥3500 | ≥4000 | ≥4500 | ≥5000 | ≥6000 | ≥7000 | |

| φ20 | ≥6000 | ≥6000 | ≥7000 | ≥8000 | ≥10000 | ≥12000 | |

| φ25 | ≥7000 | ≥7000 | ≥8000 | ≥10000 | ≥15000 | ≥17000 | |

| φ30 | ≥8000 | ≥9000 | ≥10000 | ≥12000 | ≥17000 | ≥19000 | |

| φ38 | ≥10000 | ≥12000 | ≥13000 | ≥15000 | ≥20000 | ≥22000 | |

| φ50 | ≥12000 | ≥14000 | ≥16000 | ≥18000 | ≥22000 | ≥26000 | |

| φ75 | ≥16000 | ≥18000 | ≥20000 | ≥22000 | ≥25000 | ≥30000 | |

| 50-75 | 55-75 | 60-80 | ≥80 | ≥82 | ≥85 | ||

| Kupfeka % | ≤2 | ≤1 | |||||

| kunyungudika kweasidhi,% | ≤6 | ||||||

| Alkalinity,% | ≥77 | ≥85 | ≥90 | ≥92 | ≥95 | ≥97 | |

| Refractoriness, ℃ | ≥400 | ≥500 | ≥700 | ≥1000 | ≥1000 | ≥1000 | |

| Kuramba kune kamwe kamwe kudzvanywa musiyano | Asina-kuparadza mwero ≥ 99%, hapana shanduko musimba rekumanikidza uye kumanikidza mushure mekuchinja kamwe kamwe kuri pasi pe25% | ||||||

| Inopesana nekushanduka kwekushisa kamwe kamwe | Kurasikirwa kwechiyero≥99% | ||||||

| Package | Iron drum packaging | Yakaiswa mumadhiramu esimbi, yakavharwa nePP kana mabhegi epurasitiki ePE | |||||

| Woven bag packaging | Inowanikwa mumabhegi akasimba uye anodzivirira UV-akarukwa | ||||||

| Ongorora: Dhata yehuwandu hwehuwandu ndeyekutarisa chete, kwete sehwaro hwekugamuchirwa. | |||||||

Chimwe Chiziviso: Ona Tafura 5 Yekunyura Mvura Ye99 Mabhora Ekuzadza

| 99 Kuzadza Bhora Mvura Kunyura | ||

| 99 filler | dhayamita | dhayamita |

| roll forming | φ<25mm | <5% |

| Machine press kugadzira | φ>25mm | <10% |

99.5% Technical Indicators

| Al2O3 | ≥99% |

| SiO2 | ≤0.14% |

| Fe2O3 | ≤0.04% |

| CaO +MgO | ≤0.03% |

| TiO2 | ≤0.06% |

| Na2O | ≤0.1% |

| K2O | ≤0.1% |

Physical Index ye Chemical Filler Bhora

| CONDITION | INDEX |

| kupfavisa mutoro (yb/t370-1995) | Deformation pasi pe0.2mpa pressure iri pasi pe0.6% |

| Thermal shock resistance (yb/t376.2-1995) | 1200°C pasi kusvika 600°C. 10 nguva pasina kuputika kwepamusoro |

| Reburn line shanduko (gb/t3997.1-1998) | 1400 ℃ kwemaawa gumi nemaviri, iyo yakanyanya kukosha ndeye 0.25%, avhareji kukosha iri pasi pe0.20% |

| Kuwanda kwehuwandu (gb/t2997-2000) | 3.2-3.50 g/cm3 |

| kupwanya simba | Sangana kupfuura 230 kg/cm2 |

| Inooneka porosity | 12-18% |

| Bulk density | 2.1-2.3g/cm3 |

Chemical Packing Bhora Packing

1) Kurongedza zvakajairika: bhegi rakarukwa repolyethylene rine huremu hwemambure e25kg, pamwe nepallet

2) Steel dhiramu kurongedza: 100L simbi dhiramu kurongedza, mapallets anogona kuwedzerwa